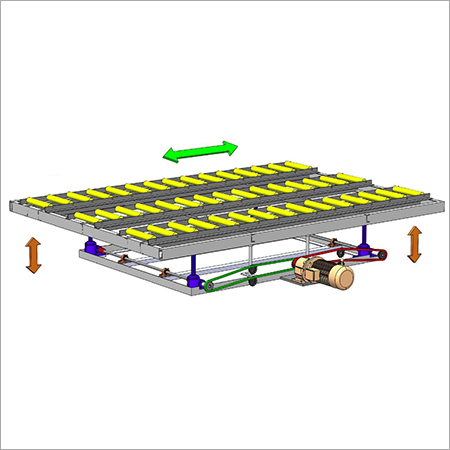

Inject Conveyor

Inject Conveyor Specification

- Usage

- Material Handling Equipment

- Size

- Different Available

- Material

- MS

- Type

- Roller Conveyor

- Structure

- Belt

- Belt Conveyor

- Flat Belt

- Roller Conveyor

- Live Powered

- Resistant Feature

- Heat Resistant

- Load Capacity

- 100 Kilograms (kg)

- Voltage

- 220-240 Volt (v)

- Warranty

- Yes

Inject Conveyor Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 1 Unit Per Day

- Delivery Time

- 4 Week

About Inject Conveyor

Backed by the rich industry understanding and market understanding, we have been able to manufacture, export and supply a quality assured range of Inject Conveyor (Feeder Conveyor). Offered conveyor is extensively used for feeding goods to the sliding belt at various places including shopping malls, airports, railway station, etc. This conveyor is manufactured under guidance of technical experts with the help of ultra-modern technology using high grade components. Besides, our clients can obtain this Inject Conveyor (Feeder Conveyor) from us at pocket friendly rates.

Features:

-

Easy installation

-

Negligible maintenance

-

Optimal endurance

-

Robust construction

|

The advantages of the systems as compared to other similar conveyors are: |

||

|

|

||

|

||

|

|

||

|

Technical Data |

||

|

|

||

|

Manufacturer / Type / model no. |

: |

DELITE / Inject Belt / INJ 100-2006 |

|

Frame size (mm) |

: |

1200x800x400 mm overall dimension |

|

Take-up. |

: |

screw type on both end rollers |

|

Length |

: |

1200 mm Meters max |

|

Load capacity (Kg / linear meter) |

: |

100 kg/system |

|

Installation height (mm) |

: |

350-400mm |

|

Speed (meter/ min.) |

: |

approx 21-25 M/min |

|

Details of Head Pulley |

: |

Dia 89 mm 5.0 mm thk mounted in Take up |

|

Block |

: |

|

|

Details of Tail Pulley |

: |

Dia 89 mm 5.0 mm thk having Bearing |

|

|

|

Sealed for life mounted inside the pulley |

|

Slider Bed Thickness |

: |

12 SWG with mounting of MS Brackets |

|

|

|

for Head and Tail Pulley duly reinforced |

|

Type of Belt. |

: |

PVC with Nylon/ EP carcass |

|

Material of belt. |

: |

PVC 2 ply Smooth or Rough Top |

|

Belt width (mm) |

: |

650 mm |

|

Thickness of belt (mm) |

: |

2.9mm |

|

Color |

: |

Black / Green based on availability |

|

Drum Motor |

: |

Interoll / BDL / TSS / Rulmeca / Emerson |

|

|

|

Cyclo / VanderGraff / Rollwell / Delite |

|

Geared Motor |

: |

Electropower / PBEGL / Bonfiglioli / Elecon / BB/ PBL / Shanti / ICBauer |

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Conveyor System Category

Cleated Belt Conveyor

Minimum Order Quantity : 1 Unit

Structure : Belt

Voltage : 220240 Volt (v)

Type : Roller Conveyor

Size : Different Available

Usage : Industrial

Release Platform Mechanical

Minimum Order Quantity : 200 Units

Structure : Belt

Voltage : 220240 Volt (v)

Type : Roller Conveyor

Size : Different Available

Usage : Industrial

Dispatch System

Minimum Order Quantity : 1 Unit

Structure : Belt

Voltage : 220240 Volt (v)

Type : Roller Conveyor

Size : Different Available

Usage : Industrial

Roller Conveyor

Minimum Order Quantity : 1 Unit

Structure : Belt

Voltage : 220240 Volt (v)

Type : Roller Conveyor

Size : Different Available

Usage : Industrial And Commercial

Head Office:

Delite Systems Engineering (India) Pvt. Ltd.,

No. 34, Guru Gobind Singh Industrial Premises,

Goregaon (East),

Mumbai 400 063,

India

Tel:+91- 22 - 2685 6404/26856778

Fax:+91- 22- 2686 6000

Branch Office:

Delite Systems Engineering (India) Pvt. Ltd.,

New Delhi

Delite Systems Engineering (India) Pvt. Ltd.,

Chennai

Send Inquiry

Send Inquiry