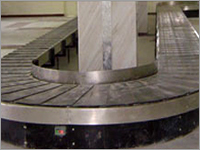

Endless Slat Conveyor

Endless Slat Conveyor Specification

- Usage

- Industrial

- Size

- Different Available

- Type

- Roller Conveyor

- Structure

- Belt

- Belt Conveyor

- Other

- Roller Conveyor

- Live Powered

- Color

- silver

- Resistant Feature

- Heat Resistant

- Load Capacity

- 100 Kilograms (kg)

- Voltage

- 220-240 Volt (v)

- Warranty

- Yes

Endless Slat Conveyor Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 1 Unit Per Day

- Delivery Time

- 4 Week

About Endless Slat Conveyor

Aiming to satisfy needs of the clients, we are engrossed in manufacturing, exporting and supplying an advanced array of Endless Slat Conveyor. In accordance with set industry norms, this conveyor is manufactured with high precision using best quality components with the aid of latest technology under the guidance of our dedicated team of experts. Offered conveyor is extensively used for conveying bags, bottles, etc., in a re-circulating way. This Endless Slat Conveyor can also be used independently or in conjunction with Belt Conveyors or X-ray machines both for Arrival Systems (Baggage Claim Conveyors) or Departure Systems (Make up Loop Conveyor).

The advantages of systems compared to other similar conveyors are:

-

Conveyor is very price competitive.

-

Usage of High Quality Superior Products and technology to manufacture the conveyor system.

-

Low noise and vibration due to superior Computer Aided Design.

-

Soft Starter / Variable Frequency Drive is used for smooth Start and Stop Operations of the system and good torque characteristics of the System.

-

Caterpillar Drive ensures Positive engagement.

-

Precision Sealed for Life Bearings are used. Drive and Load Bearings are 55mm dia.

-

Least number of parts and quickly installed.

-

Height can be easily adjusted. Minor Variations in floor level can be accommodated.

-

Modular Design and hence can be relocated extended etc. with least downtime.

-

Low number of moving parts hence less wear and tear hence less maintenance.

-

High Efficiency Systems hence Low Running Cost and less maintenance.

-

Lower Motors Capacities to run the system which translates into energy savings and almost maintenance free operations.

-

All MS parts are either Galvanised of Painted to prevent formation of Rust and giving good Aesthetics to the System.

-

Hour Run meter measures accurate Running time of the System.

TECHNICAL DATA

Some General technical Specifications are listed below. These can be changed as per specific requirement of the client.

General

|

Manufacturer / type / model no. |

: |

DELITE / Slat Conveyor / SLAT100-2006 |

|

Frame size |

: |

1000 mm Frame dimensions min |

|

Slat width (mm) |

: |

950 mm |

|

Pitch of slat |

: |

min 304.8 mm |

|

Slat material / Size |

: |

Rubber 950x450x 6mm thick |

|

Slat top finish & colour |

: |

Smooth Black Colour |

|

Conveyor width (mm) |

: |

approx. 1000 mm |

|

Load capacity Kg / Linear meter |

: |

100 Kgs / Metre |

|

Speed (meters/min) |

: |

approx. 25 1 meters/min |

|

Baggage capacity (no. of |

: |

|

|

baggage per hours) |

: |

approx 950 Bags per hour |

Chain, track, frame

|

Radius of chain |

: |

approx 1500 mm. |

|

Speed |

: |

approx. 25 1 meters/min |

|

Slat support material & thickness (mm) |

: |

MS slat Carrier min thick 5.0 m |

|

Chain track - details like material, |

|

|

|

thickness (mm) etc. |

|

|

|

a) Straight section |

: |

min MS 4.0mm |

|

b) Curved section |

: |

min MS 5.0 mm |

|

Process of filling the gaps of |

: |

butt joint and tack welding |

|

tracks sections |

|

|

|

Frame channel - details of various |

|

|

|

components & its covering material |

|

|

|

|

: |

min 5.0mm thick |

|

b> Pitch for Slat |

: |

: 305mm |

|

Details of support legs |

: |

: MS Screw type |

|

Details of toe kick plate |

: |

: MS 2.0mm Black in Colour |

|

Details of take up |

: |

: Screw type |

|

Details of trim & facia |

: |

: Formed Steel SS (16SWG) in Passenger Side |

|

|

: |

MS (14 SWG) in Non Pass Side |

|

Details of outer cover |

: |

: Formed Steel SS (16 SWG) Passenger Side |

|

|

|

MS (14 SWG) in Non Pass Side |

|

Dia of Tyred wheel & type of bearing |

: |

: 55mm dia / Precision type |

|

Make of bearing |

: |

:SKF/NTN/Equiv |

|

Minimum guaranteed |

: |

: 30,000hours |

|

life of bearing (hours of operation) |

|

|

|

Materials of tyre on the bearings |

: |

: Nylon / 15,000 hours |

|

and the life of the Tyres |

|

|

NOTE:

-

ALL Bearings including Load, Guide and in Drive Unit (if any) would be 55.0mm minimum

-

Minimum 8 Dog Drive Unit is used for Smooth and Efficient Transmission.

-

Special arrangement of brackets for fixing INFILL TRIM (by others) can be made available as an Option.

Electric Motor

|

Manufacturer |

: |

Crompton / BB / ABB / SEW / Bonfigliolli / GE / Kirloskar / IC Bauer / NORD / Siemens |

|

Rated out put (HP) |

: |

Suitable for the length of the Conveyor. |

|

Range of working voltage |

: |

415 10 Volts as per manufacturers catalogue |

|

No. of phases |

: |

3 f |

|

Frequency (Hz) |

: |

50Hz |

|

Rated speed (RPM) |

: |

1400 rpm |

|

Rated current (AMP) |

|

depending on Motor capacity |

Motor Starter

|

Whether arrangement of Soft Starter / Variable Frequency Drive for smooth |

: |

Yes |

|

Make of VFD/Soft Starter |

: |

Siemens / Crompton / LG / Telemechanique / Fuji / Yasakawa / L&T / Schneider |

|

Type of overload protection. |

: |

Bimetallic Over load Relay / VFD |

|

Type of under voltage protection. |

: |

Voltage Sensing |

|

Type of single phasing prevention |

: |

Voltage Sensing |

Drive

|

Make of reduction Gear |

: |

PBEGL / SEW / Bonfigliolli / Kirloskar / GE / ICBauer / Nord |

|

Reduction ratio |

: |

Suitable for the above speed of conveyor |

|

Type of Drive Unit |

: |

Caterpillar Type Mechanism |

MAIN MOTOR CONTROL CENTRE

|

Manufacturer |

: |

DELITE |

|

Size ( H x L & W) in mm. |

: |

min 800 mm x 800mm x 300mm |

|

MS sheet thickness (mm) |

: |

2.0 mm |

|

Bus bar material and amperage |

: |

Copper Bus bar of suitable size capacity |

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Conveyor System Category

Industrial Conveyors

Minimum Order Quantity : 1 Unit

Type : Roller Conveyor

Usage : Industrial

Voltage : 220240 Volt (v)

Structure : Belt

Size : Different Available

Telescopic Belt Conveyor

Minimum Order Quantity : 1 Unit

Type : Roller Conveyor

Usage : Material Handling Equipment

Voltage : 220240 Volt (v)

Structure : Belt

Size : Different Available

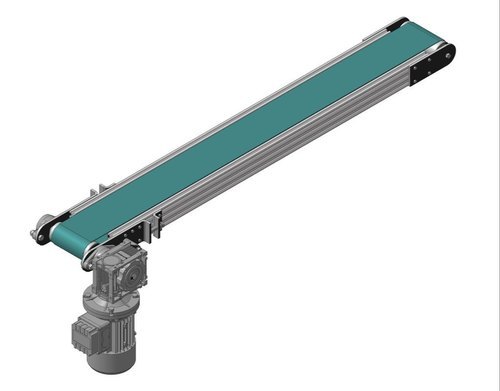

Horizontal Type Flat Belt Conveyor

Minimum Order Quantity : 1 , , Unit

Type : Roller Conveyor

Usage : Material Handling Equipment

Voltage : 220240 Volt (v)

Structure : Belt

Size : Different Available

Roller Conveyor

Minimum Order Quantity : 1 Unit

Type : Roller Conveyor

Usage : Industrial And Commercial

Voltage : 220240 Volt (v)

Structure : Belt

Size : Different Available

Head Office:

Delite Systems Engineering (India) Pvt. Ltd.,

No. 34, Guru Gobind Singh Industrial Premises,

Goregaon (East),

Mumbai 400 063,

India

Tel:+91- 22 - 2685 6404/26856778

Fax:+91- 22- 2686 6000

Branch Office:

Delite Systems Engineering (India) Pvt. Ltd.,

New Delhi

Delite Systems Engineering (India) Pvt. Ltd.,

Chennai

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS